CABLE TECH MACHINES

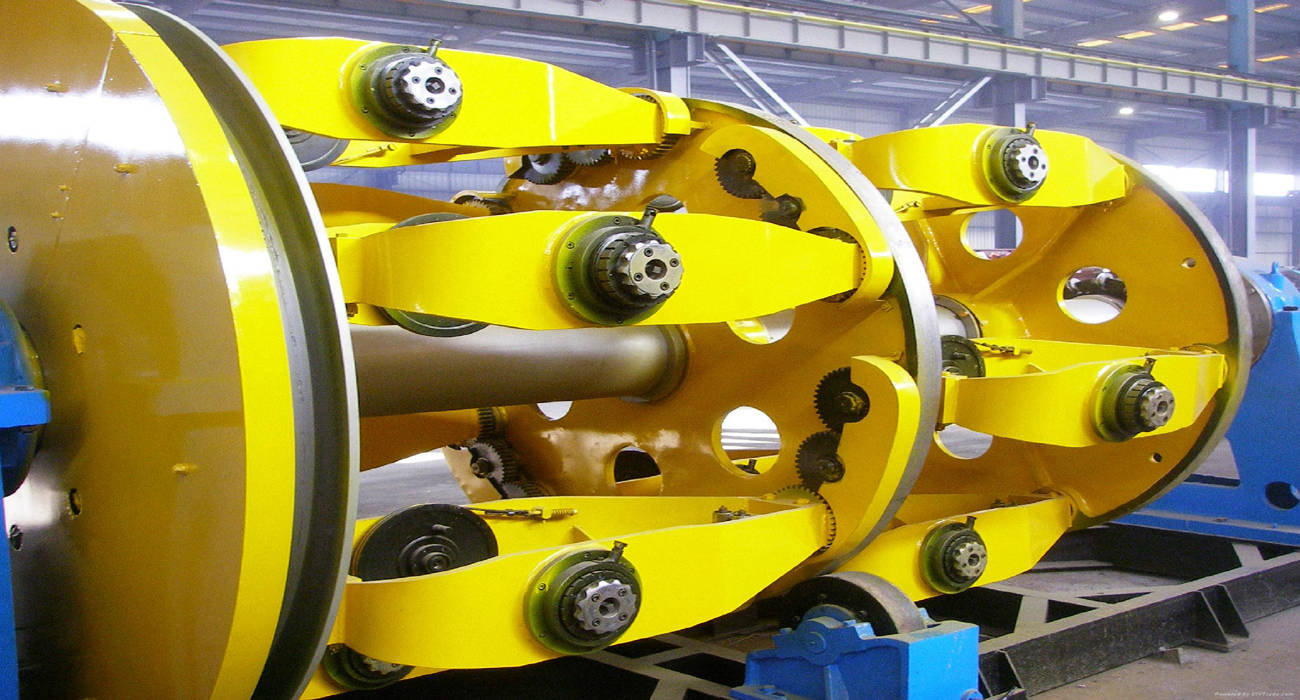

Full range of Stranding and Cabling Machines for Wire and Cable Industry

CABLE TECH MACHINES

Full range of Stranding and Cabling Machines for Wire and Cable Industry

CABLE TECH MACHINES

Full range of Stranding and Cabling Machines for Wire and Cable Industry

CABLE TECH MACHINES

Full range of Stranding and Cabling Machines for Wire and Cable Industry